F S 1 0 0 0 0 Dust Emission Flow Switch

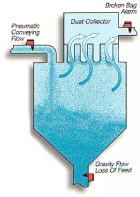

Emissions from dust collectors and bag houses has become a major environmental issue. Babbitt has two products which monitor these processes, and assist in reducing the level of dust emissions. The FS10000 Flow Switch is able to alarm and/or shut down a dust collector when a weak filter is detected BEFORE it becomes a major failure and source of dust emissions. With the FT 4100 Flow Transmitter, dust emission levels can be measured with the means to continuously record the emissions data. The FT4100 meets the requirements of EPA Title V parameter monitoring.

The FS10000 is designed to detect and alarm the flow of dust through a filter in a dust collector or a bag house. In some cases, it can also be used as a flow / no-flow switch for powders and granulars in chutes or pneumatic conveying lines.

When particles collide with the sensing probe, a small electrical charge is transferred to the probe and sensed via the FS10000's proprietary circuitry. This charge transfer is called the triboelectric effect, or "frictional electricity". The FS10000 can detect dust collector emissions before they are visible.

The FS10000's output is via an on-board relay, that may be used to sound an alarm or perform other control functions.

Features of the FS10000 Include:

- Solid state, no moving parts.

- Simple installation and calibration.

- No optics or lenses to clean or align.

- NEMA 4X enclosure for electronics.

- Optional NEMA 7 or 9 enclosure.

- Explosion-proof housing at probe.

- Field adjustable time delay.

Typical Applications

- Detect torn filters in dust collectors.

- Fabric or cartridge filter sensing.

The FS10000 is designed for applications where the velocity is 1800 feet per minute or greater. To calculate velocity when you know the CFM, use the formula below:

All necessary calibration indicators are on the remote mounted electronics, so all you need to calibrate the FS10000 is a small screwdriver. Calibration is performed under a no-flow condition. Each unit has a field adjustable time delay that may be used to ignore nuisance indications or intermittent gaps in product feed.

The FS10000 comes complete with the electronic circuit board mounted in a NEMA 4X enclosure, 15 feet of low noise coaxial cable and connectors, and a 316 stainless steel probe mounted in an explosion-proof enclosure.

An optional Shield Screen is available for the probe. The Shield Screen is designed to shield the probe from unwanted electrical noise in the duct that may be caused by nearby fans or motors. It can also shield the probe from stray static electrical charges created in non-metallic ducts. The Shield Screen bleeds the electrical noise to ground, before it reaches the probe, while allowing the dust in the air stream to collide with the sensing probe. Order information

| Power: |

120VAC (+/- 15%) 50/60Hz, standard. 230VAC optional. |

|

| Output: |

2 Form C contacts, DPDT relay, 5Amp resistive at 125VAC, 250VAC; 30VDC. |

|

| On-Board Fuse |

0.5 Amp |

|

| Time Delay: |

Selectable ON DELAY or OFF DELAY. |

|

|

Adjustable from 1/8 second to 2 hours. |

|

| Process Entry: |

3/4" NPT |

|

| Conduit Entry: |

3/4" NPT |

|

| Temperature: |

Probe: -30 deg F to +200 deg F |

|

|

Electronics: -30 deg F to 370 deg F |

|

|

Note - High temperature ratings are available, contact the factory with your application data. |

|

| Pressure: |

85 psi @ 75 deg F. |

|

|

Note - High pressure ratings are available, contact the factory with your application data. |

|

| Probe Construction: |

Probe: 1/2" diameter, 316 stainless steel. 1-1/2", 3" or 6" length standard. |

|

|

Insulator: Ultra High Molecular Weight Polyethylene (UHMWP); Teflon optional. |

|

|

Housing: Housed in a copper-free cast aluminum explosion-proof enclosure. Class I, Group C, D; Class II, Group E,F,G; Class III. |

| Electronics Enclosure: |

Non-metallic; 10" x 8" x 5" with clear acrylic window; rated NEMA 4X-12-13 |

|

|