F T 4 1 0 0 Dust Emission Flow Transmitter

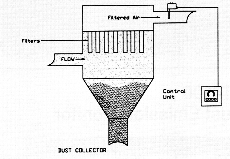

The FT4100 is designed to sense dust emissions passing through a filter in a dust collector or bag house. This very sensitive device allows the user to continuously monitor the level of emission, and record the data.

The FT4100 allows simple, no calibration, "plug and play" monitoring of filter conditions in a baghouse or dust collector. The solid 316SS probe is placed in the discharge duct of the dust collector. Dust particles passing by the probe induce an electrical charge that is carried along the low noise coaxial cable to the control unit. The control unit displays the sensed values, alarms and provides a 4-20mA output proportional to the level of emissions.

For applications that have electrically conductive dusts, condensate or moisture which would cause a build-up on the sensing probe we offer a system with a coated probe that will be unaffected by such conditions; please specify option "PP" when ordering for this option.

A semi-circular bar graph displays the dust leakage levels on a logarithmic scale (field selectable linear scale is also standard). The bar graph corresponds to a real time digital readout. A flashing "Alarm" and "Pre-Visible" message signals when set points have been exceeded. One segment of the bar graph will hold the peak value reading allowing operators to observe the peak value in a fast changing environment.

Dust emissions occur at two different times and at two different levels in a dust collector. The first is the baseline emission level, which is the normal leakage whenever the co~lector is in operation. Typically a higher emission level occurs when the filters are being pulsed or cleaned by reverse air.

The FT4100 allows the operator to precisely set the alarm setpoint when the baseline leakage increases, when the peak levels during cleaning increase or both! A time delay (0-60 seconds) is user programmable via the keypad to filter out nuisance alarms for both setpoints. One on-board relay is the output for both alarm signals. A 4-20mA signal proportional to the dust leakage is provided for recording or remote monitoring of the dust filters condition.

Features of the FT4100:

- No Calibration - Auto-Ranging.

- 2 Setpoints for Alarm.

- 4-20mA Output for Recording.

- LCD Bar-Graph Display.

- Real-Time Digital Readout.

- Peak Value Capture Display.

- Lockable Keypad.

Benefits of the FT4100:

- Comply with EPA Filter Leak Regulations.

- Monitor Filter Performance without Prior Baseline Data.

- Protect Downstream Equipment.

- Eliminate Unplanned Shutdowns.

- Prevent Product Loss and Cleanup.

The following illustration shows how a chart recorder can be used to record emission history and predict bag house or cartridge filter failure.

The FT 4100's alarm is set at 3 times over the mass level of the of dust that normally escapes through the filters. The spikes on the trend line are cause by cleaning cycles of 5-15 second duration. As worn filters or small tears appear, the spike begin to grow. Over time, the spikes continue to grow and widen beyond the FT 4100's alarm delay time. The FT4100 alarm will be triggered at this point and the system can be shut down, hopefully, before the onset of visible emissions. The FT4100 does not dampen out cleaning cycle spikes, thus providing superior alarming and recording.

The FT4100 comes complete with the electronic circuit board mounted in a NEMA 4X enclosure, 15 feet of low noise coaxial cable and connectors, and a 316 stainless steel probe mounted in an explosion-proof enclosure.

For applications that have electrically conductive dusts, condensate or moisture which would cause a build-up on the sensing probe we offer a system with a coated probe that will be unaffected by such conditions; please specify option "PP" when ordering for this option.

An optional Shield Screen is available for the probe. The Shield Screen is designed to shield the probe from unwanted electrical noise in the duct that may be caused by nearby fans or motors. It can also shield the probe from stray static electrical charges created in non-metallic ducts. The Shield Screen bleeds the electrical noise to ground, before it reaches the probe, while allowing the dust in the air stream to collide with the sensing probe.

Ordering Information

| Power: |

120VAC 50/60Hz standard. 24VDC is optional. |

| Fuse: |

On-board 0.032 Amp |

| Analog Output: |

4-20mA output proportional to display. Non-isolated, 500ohms max. |

| Relay Output: |

1 Form C contact, SPDT relay, 5Amp resistive at 240VAC; 24VDC. |

| Sensor: |

Passive sensor. No voltage or active components. |

| Intrinsic Safety: |

Intrinsic Safety Barrier is built into the control unit. |

| Display: |

Semi-circular LCD display in logarithmic or linear scale. |

|

Real-time digital display. Peak value indication. "Alarm" and "Pre-Visible" indication. |

| Time Delay: |

ON DELAY selectable for 1, 5 or 30 seconds. |

| Process Entry: |

3/4" NPT standard. 1.5" triclamp quick-connect optional. Probe air purge is available as an option with both connection types. Coated probe for wet or conductive applications is available as an option. |

| Conduit Entry: |

3/4" NPT standard. 1.5" triclamp-clamp quick-connect optional. |

| Temperature: |

Probe: -30 deg F to +400 deg F |

|

Electronics: -13 deg F to 160 deg F |

|

Note - High temperature ratings are available, contact the factory with your application data. |

| Pressure: |

85 psi @ 75 deg F. |

|

Note - High pressure ratings are available, contact the factory with your application data. |

| Probe Construction: |

Probe: 1/2" diameter, 316 stainless steel. 3", 6" or 12"length standard. |

|

Insulator: Teflon. |

|

Probe Housing: Copper-free cast aluminum explosion-proof enclosure. Class I, Group C, D; Class II, Group E,F,G; Class III. |

| Electronics Enclosure: |

Non-metallic; 7" x 7" x 5" with membrane keypad and clear acrylic window; rated NEMA 4X-12-13 |

| Sensitivity: |

Standard: 5.0 to 5000 pA |

|

Optional: 0.5 to 500 pA |

| Particle Size: |

>0.3 micron |

| Air Velocity: |

300FPM or higher |

| Accuracy: |

+/- 5% of output range |

|

|

|